how to check rockwell hardness test|rockwell hardness test procedure pdf : custom The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .

WEB30 de nov. de 2023 · Delivery gone wrong caught on camera. November 30, 2023. A Surrey man says his recent FedEx delivery went terribly wrong. His home security .

{plog:ftitle_list}

27 de abr. de 2022 · Private55.com. 285 likes. Somos o melhor site que você irá conhecer! Em 20 cidades e crescendo.

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .Rockwell Testing Machine. This is probably the most common way of professionally and accurately checking the hardness of metals. A rounded . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart. How to Calibrate a Rockwell Hardness Tester. What is the Standard for the .

The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .

types of rockwell hardness test

rockwell hardness test scale

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative .Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

Introduction. When manufacturing metal components of any kind, it’s important to have control over the properties of a finished part. To ensure that your finished product meets all the necessary specifications, you might need to perform a Rockwell hardness test on a metal part or test sample at different points during production. It is useful to check the hardness of steel and .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested. Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. We depend on the data produced to verify heat treatment, structural .

Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The . Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .

rockwell hardness test procedure pdf

The RockGen Rockwell Hardness Testing System was designed to test the hardness level of metal based on the indentation they leave on a tested material according to the Rockwell scale. The machine is capable of measuring the resolution of a material to a 0.001″.The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter has been forced into the specimen material at a given load. . Check out our range of .

The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf. Therefore, a ground surface is usually sufficient, and sometimes no preparation is required. . Check out our complete range of Duramin hardness testers.For this test, the indenter on the Rockwell hardness testing machine is a tungsten carbide ball of four different sizes or a diamond indenter. During the test, the indenters with a set of known loads cause an impression on the material surface by applying an initial small load followed by a greater final load to drive the main impression. The .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .Rockwell Hardness Test; Rockwell hardness test method utilizes a Rockwell hardness testing machine equipped with either a tungsten carbide ball indenter or a diamond indenter. For the ball indenter, four different sizes exist, while the diamond indenter only exists as a single type. However, the loads required to carry out this test ranges from .

measuring cr3 thickness

Hardness Conversion for Rockwell C Scale or High Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. . To obtain the best results, you should be aware of any special techniques that can be used to improve the test method. Rockwell Hardness Testing. Because of its low force, high speed, and nondestructive nature, . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. . Check out . HRC Rockwell Test - DIY Hardness TestUsually, harder steel increases the likelihood that blade will remain sharp for a longer period of time. Steel hardness .

The Rockwell hardness test involves indenting the surface of a material with a diamond cone or steel ball indenter and measuring the depth of the resulting indentation. Significance of Rockwell Hardness. Rockwell hardness is significant because it is a quick and easy method of measuring the hardness of a material. It is also a reliable method .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Many Rockwell test standards also stated that while processing the test, there should be a distance of more than 2.5 times the diameter of the indentation between mid of an indentation and the periphery of the material. Thickness of Test Material In the Rockwell hardness test, indentation depth depends on the thickness of the material.

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of the indentation as the force on the .Here are the most popular methods of hardness testing. Rockwell Test – Using a Rockwell hardness testing machine helps to carry out this test. It also includes a ball indenter made from tungsten carbide in four different sizes that causes a depression when it is released on the surface of the material. A diamond indenter is also used .

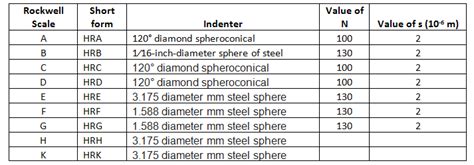

German mineralogist Mohs first devised the Mohs hardness test to measure the scratch hardness of materials. In this test, the material is scratched with a reference material that has a defined hardness. A numerical hardness value is assigned to the test material based on the results of the test. Mohs hardness test uses 10 reference materials of . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell B Scale. Used to test: aluminum, brass, and softer steels. Rockwell C Scale. Used to test: harder steels. For stainless steel plates or strips exceeding 1.2mm in thickness, the Rockwell hardness test is the preferred method. This test utilizes either the HRB scale (with a 1/16-inch steel ball indenter) for softer grades or the HRC scale (with a diamond cone indenter) for harder grades. The Rockwell test offers rapid results with minimal surface . Two levels of force are applied to the indenter at specified rates and dwell times when performing a Rockwell hardness test. This is different than the Brinell and Vickers tests, where the size of the indentation is measured after the indentation process. The Rockwell hardness of the material is based on the difference in the depth of the .

rockwell hardness test procedure

Eu sei que sempre estás comigo, Senhor Também sei que n.

how to check rockwell hardness test|rockwell hardness test procedure pdf